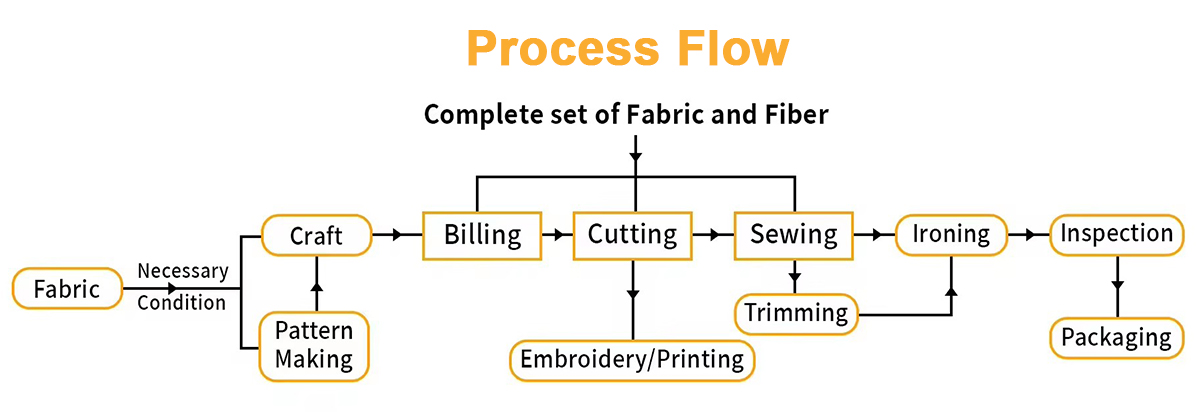

Customising hats is a multifaceted process involving many steps, each of which is carefully executed to ensure that the final product meets the customer's specifications. As shown in the flow chart, the hat order process outlines the entire process from initial fabric selection to final packaging. Each stage of the process is described in detail below.

Fabrics:

The journey begins with the selection of a complete set of fabrics. This choice is critical as it determines the durability, comfort and overall aesthetics of the hat. The fabric undergoes the necessary conditioning process to prepare it for production and to ensure that it performs as expected during the manufacturing process.

Craftsmanship and Pattern Making:

Once the fabric is ready, the production phase begins with pattern making. Skilled designers translate the client's vision into a tangible pattern. This involves creating a template to guide the cutting and sewing process, ensuring that each piece fits together perfectly.

Billing and Cutting:

Once the final pattern has been determined, billing takes place and the pattern is marked on the fabric. Then comes the cutting stage, where the fabric is accurately cut according to these markings. This step requires precision to ensure that all pieces are properly aligned during assembly.

Embroidery/printing:

For hats that need to be personalised or branded, embroidery or printing is the next step. This may include logos, text or intricate designs. The choice between embroidery and printing depends on the complexity of the design and the level of finish required.

Sewing and trimming:

After cutting the pieces and applying any trim, the sewing process begins. This is where the hat begins to take shape as the pieces are sewn together. Once sewn together, trimming is required to remove any excess fabric or thread to improve the appearance of the hat.

Ironing:

Ironing is crucial to creating a professional look. It helps to shape the hat, especially the brim and top, and remove any wrinkles in the fabric. This step ensures that the hat retains its intended shape.

Inspection and Packaging:

The final stage includes a thorough inspection to check for any defects or inconsistencies. Only hats that pass the quality inspection are packaged. Packaging not only protects the hat during shipping, but also enhances its appearance, reflecting the care taken throughout the production process.

This comprehensive process emphasises the attention to detail and craftsmanship that goes into making a custom hat. Each step is essential to help make the final product both functional and stylish, tailored to each customer's unique needs and preferences.