For men, golf sun hats have an open-top design, men's sun visor wide brim golf hats which allow a circular area for the head to be exposed to the air without any discomfort. Besides the large brim of golf sun hat is also a sun and wind protector, preventing the eyes from receiving the light and giving a cool shade to the face to protect the skin from sunburn.

The hats for men can be worn during various outdoor activities such as jogging, tennis, golf, baseball, horse riding, hiking, gardening, and other sports.

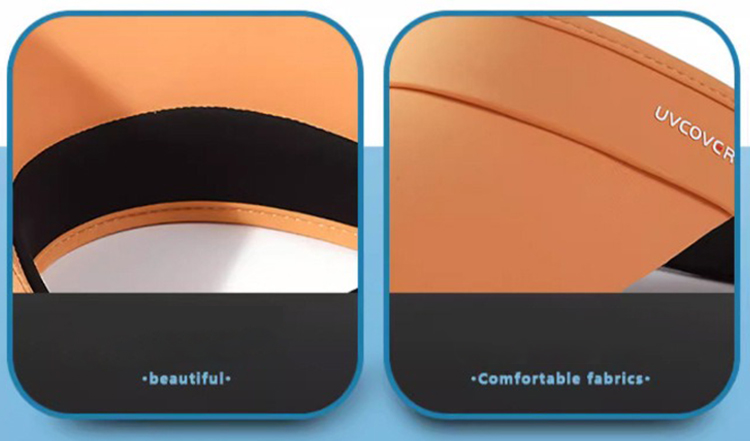

1. Sun Visor Cap Wide Brim Design

The large brim is the most important characteristic of a golf sun hat. It allows your face and neck, the areas that are the most exposed, to be covered against the sun's rays.

2. Mens Sun Visor UV Protection

Pick a golf sun hat for men which is solely intended for providing maximum protection from UV rays. These wide brim golf hats are made of a special fabric that effectively blocks the UVA and UVB rays.

3. Mens Sun Visor Lightweight and Breathable Materials

Light and airy fabrics are used in a sun visor cap so that you will barely feel the weight of the cap and you are sure to stay cool. visor

4. Sun Visor Cap Adjustable and Secure Fit

Using the adjustable fit option, it can be ensured that even the most powerful and energetic swing will not dislodge the wide brim golf hats.

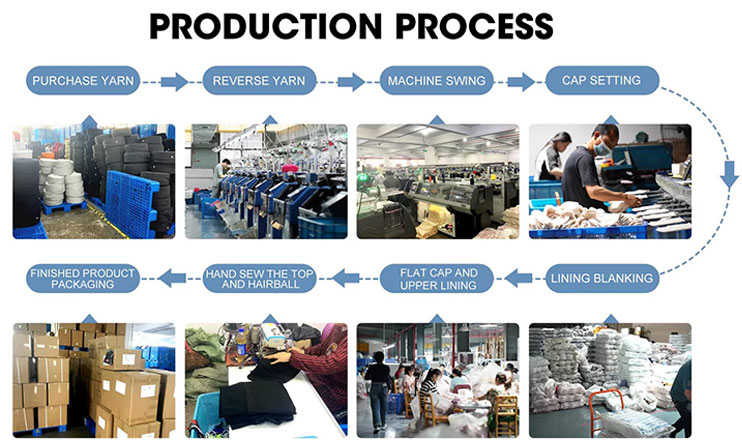

1. Purchase of yarn

The first step of the production process is the successful procurement of top-notch yarn. We pick the yarns that are appropriate for the types of hat designs in a very careful way so that we can be sure of the high quality of the raw materials.

2. Yarn in reverse

The yarn that has been purchased should be yarn in reverse treated so that the uniformity and the consistency of the yarn which, in turn, is very important for the following weaving process.

3. Machine Swing

After the reverse yarn is done, a braiding machine is used for the yarn to be woven. This procedure guarantees the production of a constant quality and the efficiency of the process.

4. Shaping a cap

The braiding hat requires to be shaped which means the shape and the size of the hat should be according to the design requirements. This step is necessary for the look and the comfort of the hat.

5. Lining Blanking

Not only the lining but also the lining of the hat should be finished with the perfect fitting. This stage requires the cutting and sewing to be made with absolute precision.

6. Flat Cap and Upper Lining

In order for the hat's overall look and structure to be maintained, the top and the upper lining of the hat should be removed and kept flat.

7. Hand Sew the Top and Hairball

Generally, hairballs or other top decorations are hand sewing on hats which is a method that secures both the firmness and the beauty of the decoration.

8. Finished Product Packaging

After the production process, the hat undergoes a quality control test and then it is packed for delivery. We ensure the safety of the packaging in order to avoid the product from being damaged during the transport.

NUMBER ONE®. became a modern enterprise in 2009, with professional R & D design team, production, sales and brand operation as one.

We are the most professional manufacturer, can provide you with the most professional OEM/ODM service.

NUMBER ONE operates a state-of-the-art factory spanning over 20,000 square meters and is supported by a dedicated team of more than 300 professionals. With 10 highly efficient production lines, NUMBER ONE produces over 30 million units annually and launches more than 100 new products each month.

NUMBER ONE company cooperate with leading brands such as Puma、Disney, and Champion etc, exporting its products to more than 20 countries and regions, including Russia, Southeast Asia, the Middle East, North America, and South America. NUMBER ONE continuously enhances its global presence by participating in renowned international exhibitions.

WE have earned us key sustainability certifications, including GRS, OCS, and FSC

Our factory is equipped with state-of-the-art machinery and equipment, including high-speed sewing machines, automatic cutting systems and advanced fabric printing technology. These state-of-the-art tools increase productivity and ensure the quality of every garment we produce.

Professional Product Testing Center

Product quality inspection and testing center to ensure product quality, provide comprehensive testing services, help enterprises to enhance competitiveness, protect consumer rights and interests, and promote international trade.

Inspection and Packaging

We have a professional QC team to quality check the football jerseys, including meticulous inspection of the design and materials for any defects or discrepancies. After inspection, the football kits are neatly folded, labeled with sizes and colors, and securely packaged for distribution.

FAQ

What materials can I choose from for my custom golf hats?

We have a large selection of materials such as 100% cotton, polyester, blends, and more. Every fabric has its own features for instance breathability, durability, and so on.

Can I add a logo or graphic to my custom cap?

Of course! Apart from embroidery, we also offer printing service for your logo, image, or text on the cap. Our production team is able to do it for you if you give them your artwork.

How many colors can I use for my cap design?

First of all, you can pick any color from our wide range of colors to make your hat or cap whatever color you want. In addition, you are not even limited to the number of colors. Yet, there may be an increase in your custom cap price if you use more colors.

What sizes do you offer, and do you have adjustable caps?

The sizes we offer are for the most part suitable for one head of average size and there is an adjustable snapback or strap so that a comfortable fit for the range can be achieved.

What is the minimum order quantity for custom baseball caps?

The minimum number of products you can order is subject to the customization details and options selected. We are open to small orders for presents and big orders for corporate events or team uniforms.

How long does it take to produce a custom baseball cap?

The waiting time in production depends on how elaborate the design is and the number of pieces ordered. Usually, it is a time span of 2-3 weeks from the design finalization to the delivery.

Can I get a sample before placing a large order?

Yes! To check the quality, we can send you a sample. It will decide if you want us to proceed with the full order or not.

How do I care for my custom baseball cap?

Most of our hats can be machine washed. We recommend that you turn the hats inside out and wash them on a gentle cycle with cold water and a mild detergent. To retain the shape of the hat, use a low setting for the tumble dry.

Is it possible to return or exchange a custom cap if I am not satisfied?

Our caps are made according to customers' specifications; therefore, returns and exchanges must be authorized by us. If the materials or workmanship of the product is defective, then we will be happy to take care of it with you.

Do you ship internationally, and what are the shipping costs?

Yes, we do. The shipping cost depends on the destination and the package's weight. We will be able to give you a shipping rate during the checkout process.

NUMBER ONE®, a key subsidiary of IBMC Group, specializes in the producing sportswear and accessories.

Copyright By ©Number One Industrial Co., Ltd.